Igwe eji agbado ọkụ na-echekwa ike na-ebugharị

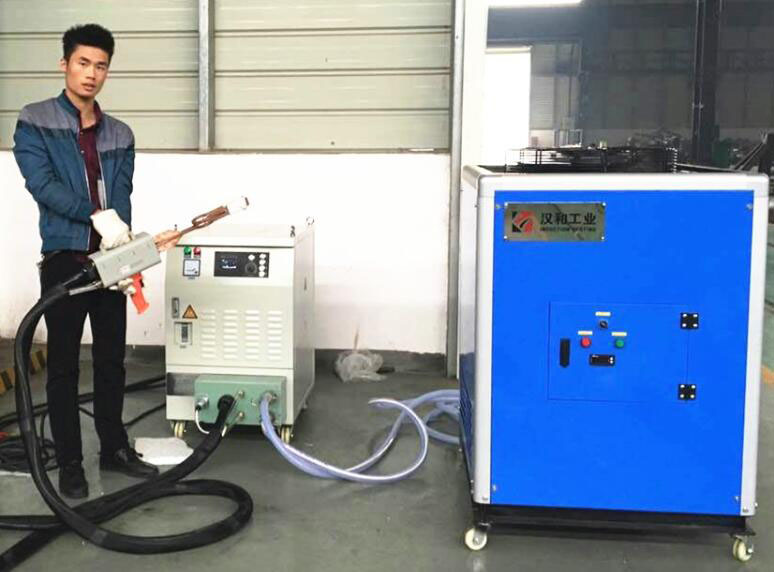

Ihe mejupụtara

Igwe mgbado ọkụ induction nwere ọgụgụ isi bụ nke transistor nnukwu ọkụ ọkụ ugboro ugboro, eriri mmepụta dị nro dịpụrụ adịpụ, eriri ọkụ induction, eriri eriri mmepụta, ụlọ elu jụrụ oyi wdg.

Atụmatụ

Ọkụ ọkụ ọkụ nke ngwaahịa a na-anabata ngwaọrụ mkparịta ụka transistor IGBT kachasị dị elu nke ukwuu, nke na-agbanwe ike eletrik ugboro atọ nke Hz ka ọ bụrụ ike ọkụ eletrik dị elu nke otu oge.Akụrụngwa a na-etinye ụkpụrụ nke induction electromagnetic iji tinye mpempe ọrụ na mpaghara ndọta ọzọ n'okpuru gburugburu ikuku, ikuku na gas na-echebe, nke na-emepụta mfu ugbu a ma na-emepụta okpomọkụ, nke na-emezu ihe achọrọ nke ịgbaze diathermy na quenching.Ụzọ kpo oku a nwere uru nke oke ọkụ ọkụ, obere ọkụ ọkụ, obere ọrụ ike na ezigbo ngwaahịa.E jiri ya tụnyere tube eletrọnịkị nke oge ochie, ọ nwere ike ịzọpụta ike site na 35% na 20% ma e jiri ya tụnyere oge ochie thyristor media cha cha cha cha, ọ nweghịkwa mkpọtụ SCR ọkara.Site na arụmọrụ dị elu nke ukwuu, ngwaahịa a nwere ọnọdụ enweghị ike dochie ya na ụlọ ọrụ ịgbado ọkụ na ụlọ ọrụ ọgwụgwọ okpomọkụ.

Ihe osise zuru ezu