Ebe ngwaahịa

-

Ọkụ na-agbaze ugboro ugboro dị elu maka Pr...

A na-eji ọkụ ọkụ induction dị elu na-agbaze ma tụba ọla dị oke ọnụ ahịa dị ka ọla edo, ọla ọcha wdg, etinyere n'ihe ịchọ mma na nka maka nnukwu ụlọ ọrụ na-eji ọla edo na obere ọnụ ahịa.

-

Ngwa igwe ntụ ntụ Spherical Spherical Gas Atomization Akụrụngwa

Ngwa atomization gas bụ maka imepụta ntụ ntụ na ntọala VIGA nke Europe.A na-eji ya maka ụlọ ọrụ R&D na mahadum iji mụọ ntụ ntụ okirikiri na ọkara okirikiri yana mmepụta oke maka ụlọ ọrụ.

-

Mmiri-Gas jikọtara Atomizer maka Soft Magnetic A...

Ngwa atomization nke ikuku jikọtara ọnụ bụ ihe nwere ọgụgụ isi, nke na-arụ ọrụ nke ọma na nke dị elu nke a na-ejikarị eme ihe maka nkà na ụzụ dị elu na mmepe na mmepụta ihe ọhụrụ na mpaghara dị ka ikuku ikuku, ụgbọ elu, na ọgụgụ isi.Ụkpụrụ na-arụ ọrụ nke akụrụngwa bụ tumadi site na induction kpo oku agbaze, nke na-agbaze ma na-ekpuchi metal siri ike ihe site na induction kpo oku.A na-awụsa mmiri mmiri igwe gbazere n'ime ite etiti, ma na-esi na ọkpọkọ ntuziaka na-aga na ngwaọrụ atomization.Mgbe ọ na-asọfe site na efere ịgbasa na pipeline atomization, a na-agbapụ mmiri dị elu site na nrịbama dị elu nke efere ịgbasa iji mepụta mpaghara atomization. ma na-eme ka mma na arụmọrụ nke ngwaahịa ahụ dịkwuo mma, karịsịa maka mmepụta nke ihe ndị nwere nnukwu ọrụ mmepụta ihe magnetik chọrọ.

-

Electrode Rotating Induction Heating Vacuum Gas...

EIGA electrode induction na-agbaze inert gas atomization akụrụngwa na-agbaze & na-emezi ihe mgbochi electrode prefabricated na gburugburu gas inert na-enweghị seramiiki crucible.Igwe a wụrụ awụ na-agafe n'ọnụ mmiri ahụ na-aga n'ihu na kwụ ọtọ.A na-egwepịa ọla ahụ a wụrụ awụ wee tụba ya n'ọtụtụ obere ụmụ irighiri mmiri site na nrube ikuku dị elu, ụmụ irighiri mmiri ndị ahụ na-agbasikwa ike n'ụgbọ elu na-etolite ntụ ntụ okirikiri.A na-eziga ngwakọta gas ntụ ntụ na nkesa cyclone jụrụ oyi maka nkewa site na tube mbufe.A na-anakọta ntụ ntụ ọla dị mma n'ime ebe a na-anakọta ntụ ntụ mechiri emechi.

-

Mechanical Induction Heating Pipe Bending Machine

WGYC serial ọkpọkọ ekwe igwe bụ idozi ma nsọtụ nke ígwè ọkpọkọ.Tọọ radius na-ehulata n'otu nsọtụ, ma mee ka nsọtụ nke ọzọ gaa n'ihu ka ọ gbadaa na ọsọ ọsọ mgbe niile.Ọkpụkpụ ígwè na-ekpo ọkụ na mpaghara site na eriri induction induction.Mgbe ọ na-ehulata, a na-ebugharị ọkpọkọ nchara site na paịlị dị elu nkenke nkenke wee mee ka ọ dị mma na-aga n'ihu na-eji usoro nju oyi kwesịrị ekwesị gaa n'akụkụ nkuku achọrọ.Enwere ike iji ya mee ihe na-ekpo ọkụ na-ehulata ụdị dị iche iche nke gburugburu ma ọ bụ square ígwè ọkpọkọ, igwe anaghị agba nchara na joist ígwè, na ọ na-emetụta mmanụ ụgbọala, chemical ụlọ ọrụ, metallurgy, ígwè Ọdịdị na ji esi mmiri ọkụ wdg.

-

Igwe anaghị agba nchara Pipe Bender na Spool na-ehulata

The induction pipe bender na spool na-ehulata na-eji ngwaọrụ ntụgharị maka 3D bends.Ngwaọrụ na-atụgharị na-eme ka tube / ọkpọkọ gbanwee na-akpaghị aka site na 90 Celsius, nke pụtara na 3D bends (spools) nwere ike ịmepụta karịa nke akụ na ụba na kpọmkwem.

-

Igwe ọkụ ọkụ nke Polysilicon Ditrctional Solidification

Igwe ọkụ ntụzịaka nke ntụzịaka bụ ngwa ọgbara ọhụrụ na-arụ ọrụ maka ịgbaze metal ma ọ bụ alloy nwere ọkụ induction ugboro ugboro n'okpuru oghere, na-akpụ gradient nke nwere ọkụ pụrụ iche na sistem jụrụ oyi, na-akwado maka sie ike na otu-kristal site na-adọkpụ ala.Ọ nwere ike ịchịkwa okpomọkụ na ọdịnaya alloy nke ihe.Iji nweta gradient okpomọkụ kachasị elu yana ngwa ngwa siri ike, a na-anabata ya na nhọpụta pụrụ iche maka ihe achọrọ maka gradient okpomọkụ.A na-emepụta ọkụ ọkụ nrụzi ntụziaka anyị n'ụzọ kwụ ọtọ na obere mpaghara na-arụ ọrụ na ogbako.

-

Igwe atomizing mmiri 100kg maka ntụ ntụ ígwè

Usoro atomization nke mmiri na-ezo aka na usoro nke na-agbapụta ma na-agbakọta mmiri na nnukwu nrụgide nke ihe dịka 50-150 MPa megide metal a wụrụ awụ na-agbaze na okpomọkụ dị elu iji mepụta ezigbo ntụ ntụ (atomized powder) na ọkwa micron.Mgbe a gbazere alloy (ọla) gbazere ma nụchaa n'ime ọkụ induction, a na-awụsa mmiri igwe a wụrụ awụ n'ime ihe nchekwa nchekwa ọkụ wee banye na tube ntụgharị.Mmiri dị elu nke na-esi na tray na-agba mmiri ga-egwepịa ma mebie mmiri igwe ahụ n'ime obere ụmụ irighiri mmiri.Mmụba nke igwe ga-agbasi ike wee daa n'ụlọ elu atomization, wee daba n'ime tank nke na-achịkọta ntụ ntụ.A na-enyocha slurry ntụ ntụ anakọtara site na akpịrị ịkpọ nkụ, ihicha na nyocha.

-

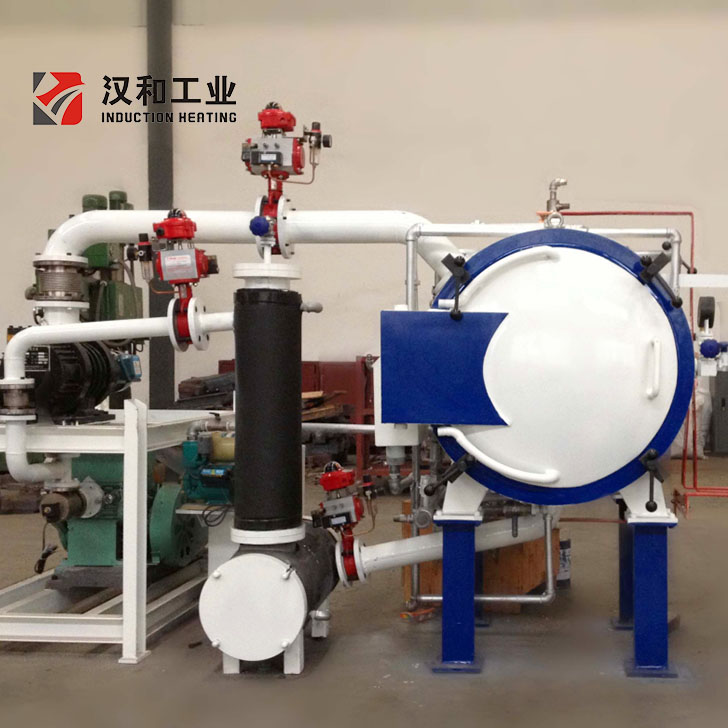

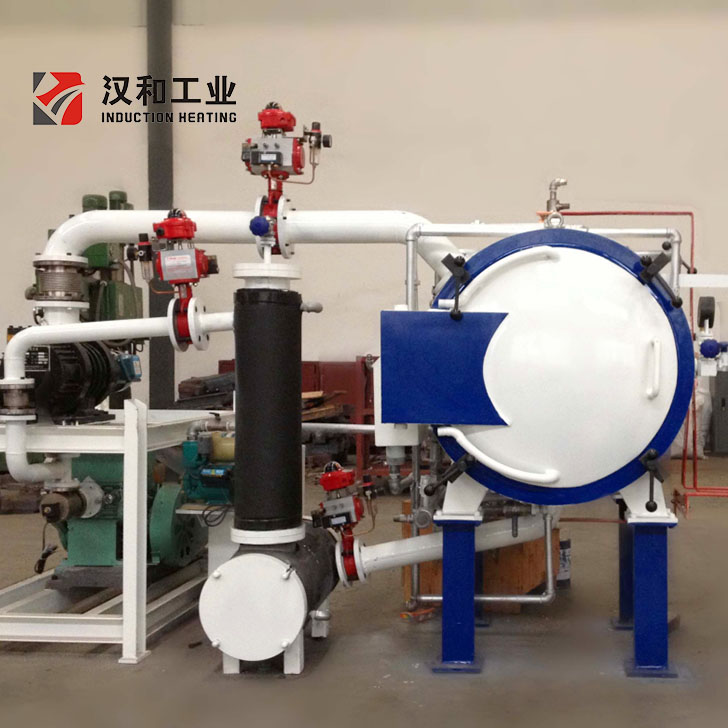

Okpomọkụ dị elu zuru oke akpaaka Sintering vacuu...

Ọkụ na-ekpo ọkụ na-ekpo ọkụ bụ ọkụ na-eji ọkụ induction na-ekpochapụ ihe ndị ekpo ọkụ na-echebe.Vacuum induction sintering oven bụ akụrụngwa zuru oke maka itinye ntinye carbide na ntụ ntụ dị iche iche site na iji ụkpụrụ nke ikuku induction ugboro ugboro n'okpuru oghere ma ọ bụ ọnọdụ ikuku nchebe.Emebere ya maka mmepụta mmepụta ihe nke ihe siri ike, metal dysprosium na ihe seramiiki.

-

Igwe ọkụ eserese dị elu

Igwe ọkụ eserese bụ ngwaọrụ nrụpụta nke nwere ike ịme graphite site na nkume dị iche iche na kemịkalụ dị iche iche.Enwere ike iji ya na-emepụta ihe ndị graphite nwere àgwà dị elu, arụmọrụ dị elu na ike eletrik eletrik.Enwere ọtụtụ ụdị ọkụ graphite, ụdị ụgbọ elu nkịtị, vetikal, ụdị nkwusioru, ụdị mmiri mmiri na ihe ndị ọzọ.

-

Otu ọkụ Uto kristal

A na-akpọkwa ọkụ ọkụ otu kristal mono crystal, ọ bụ ngwaọrụ na-agbaze ihe polycrystalline dị ka polysilicon na graphite heaterin gas inert gas (nitrogen na helium gas) gburugburu ma na-eto otu kristal na-enweghị nkwụsị site na iji usoro ịdọrọ ozugbo.

-

Ọkụ na-agbaze oghere ahaziri ahazi

Vacuum Induction Melting (VIM) bụ agbaze nke igwe site na ntinye electromagnetic n'okpuru oghere.Ọkụ induction nke nwere crucible mkpuchi mkpuchi mkpuchi gbara ya gburugburu dị n'ime ụlọ oghere.Ọkụ induction ejikọrọ na isi iyi ọkụ n'otu oge na-ejikọta ya na nha ọkụ na ihe a na-agbaze.